CLAIBORNE

CONSTRUCTION

& ENGINEERING

SERVICES

BILL OF MATERIAL OPTIMIZATION

Claiborne Construction & Engineering offers unmatched expertise in prioritizing your Bill of Materials (BOM) and optimizing SAP processes and procurement, to ensure projects not only meet, but also exceed your budgetary expectations.

With over 20 years of experience as a plant manager at Nestle, our leadership understands the intricacies of managing large-scale projects and the importance of precision in material and process management.

We bring this deep industry knowledge and organizational acumen to every client interaction, ensuring that your project’s BOM is both cost-effective and efficiently managed.

Our commitment to excellence and our proven track record in delivering on promises make us the perfect partner to enhance our project’s success while tightly aligning with your financial goals.

Trust Claiborne Construction & Engineering to bring advanced solutions and seasoned leadership to take your project to the next level.

Services As Needed |Upon Request

Claiborne Construction & Engineering offers services designed to meet your needs. Send us an email describing your needs and we will find or create what you need.

SERVICES

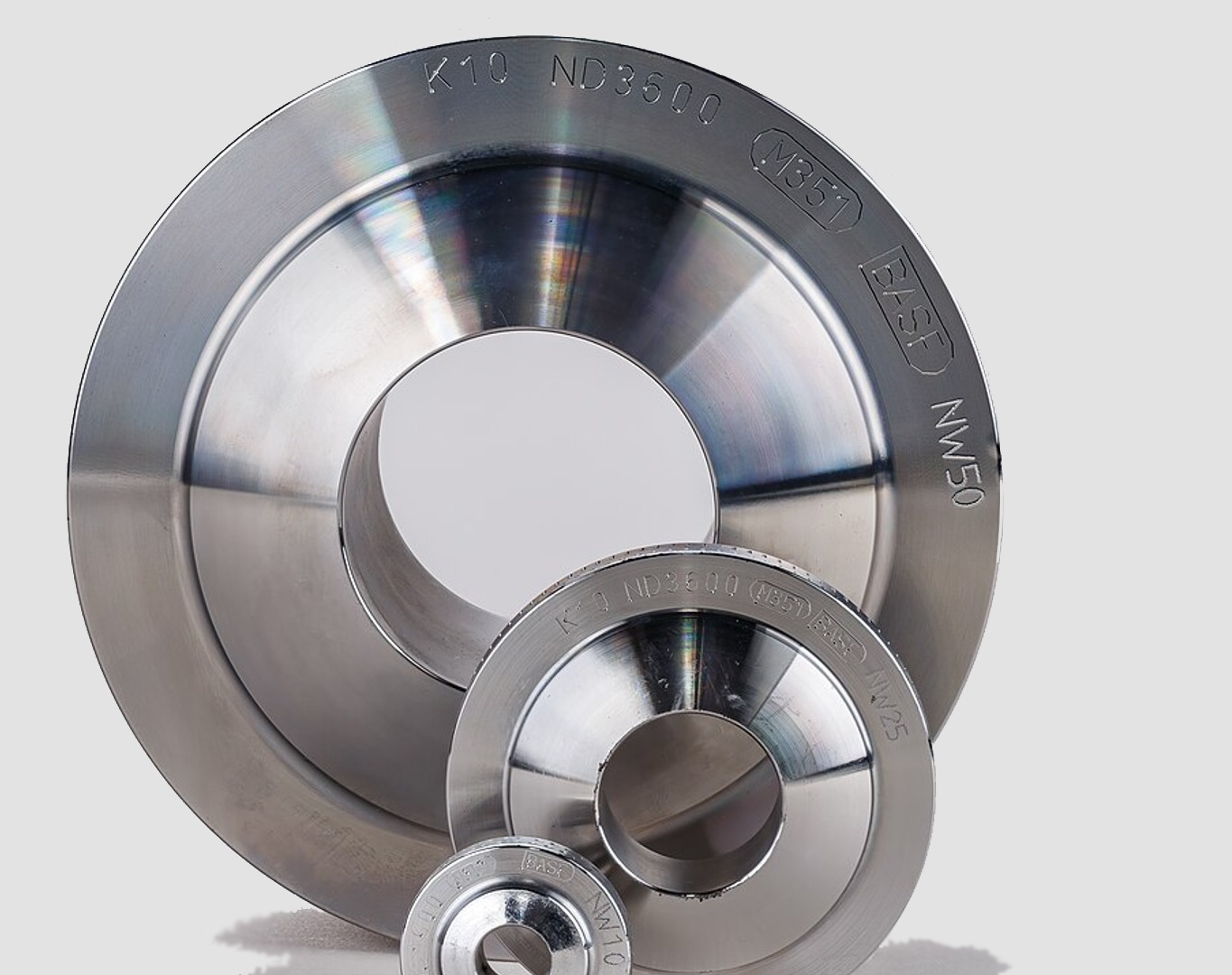

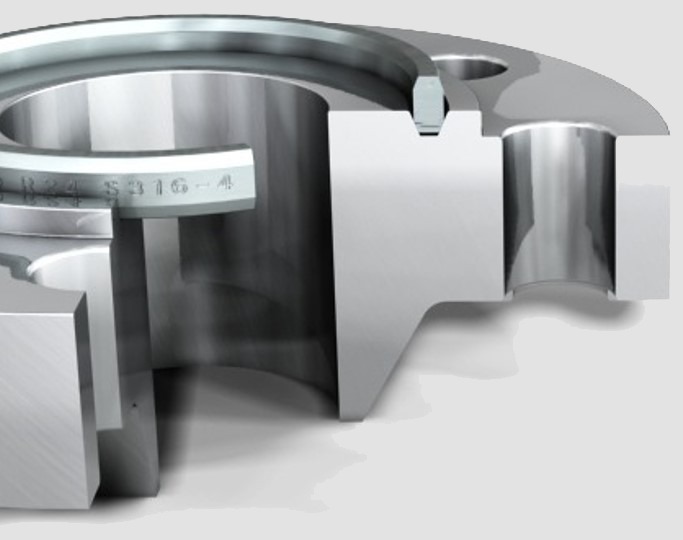

Lens Ring Gaskets & Metal Ring Gaskets Specifications

- We have proprietary processes to ensure that your gasket has the correct softness to the harder surface on the flange is not compromised.

. - Many of the gaskets do not have the correct harness whether it is measured in Rockwell or Brinell. We guarantee that our gaskets are as soft as you specify.

Lens Ring Gaskets & Metal Ring Gaskets

- Lens ring gaskets are characterized by a spherical sealing surface that touch the conical surface of the flange. These gaskets are used in special application with specific values of pression, temperature and changes during the time.

- Usually, you can find these gaskets on flange connections of high-pressure reactors where there are heavy working conditions, and a perfect sealing is needed. In this case a loss of material could comport high risks both for the workers and the environment.

- The Lens Ring offers a metallic gasket design with spherical seating faces tailored to fit precisely into mating flange recesses. This configuration delivers a high-integrity, high-pressure/temperature metal-to-metal seal. Like other metallic gaskets, the Lens Ring material should be chosen to be softer than the flange material. This ensures that the applied compressive load primarily causes elastic/plastic deformation of the lens ring rather than the flange sealing face. By distributing high compressive loads, the gasket facings spread, effectively preventing over-stressing of the gasket.

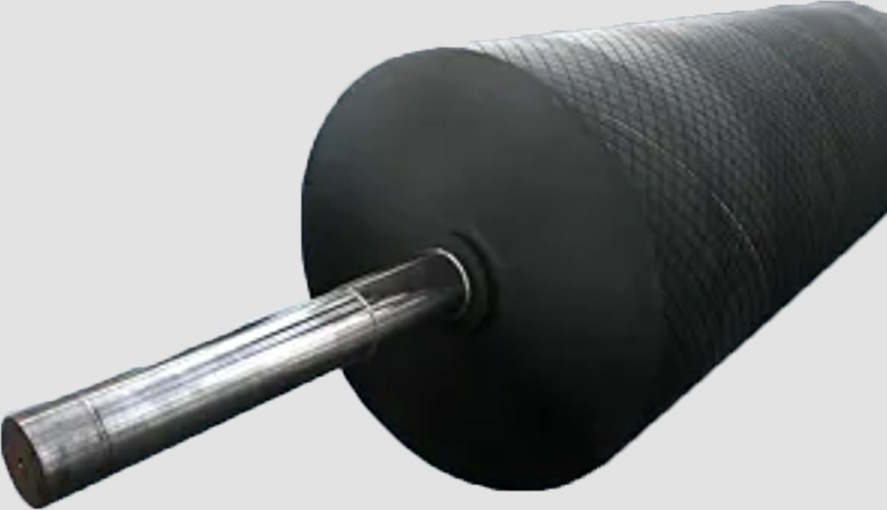

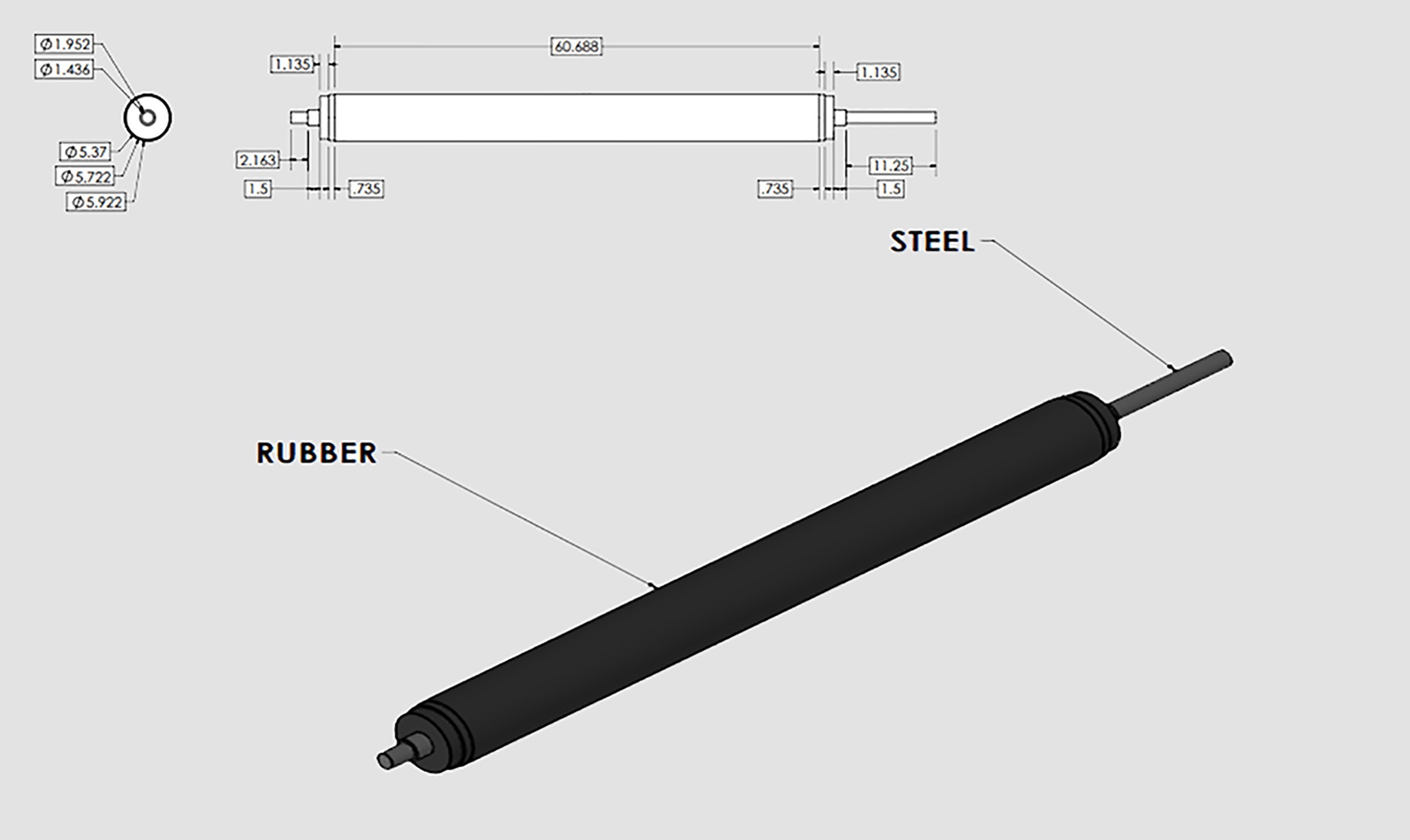

Drive Pullies & Tail Rollers

-

Rubber drive rollers are cylindrical components commonly used in various industrial applications to facilitate the movement or transportation of materials. These rollers are typically made of rubber or rubber-like materials, which provide excellent friction and traction properties.

.

-

One of the key functions of rubber drive rollers is to transfer power or motion from one rotating shaft to another. They are often utilized in conveyor systems, printing machines, packaging equipment, and other machinery where controlled movement or feeding of materials is essential.

First Phase of the Process

- Material Selection: The first step is to choose the appropriate rubber material for the roller. Factors such as hardness, resilience, resistance to abrasion, and compatibility with the application environment are considered during this stage.

- Core Preparation: The core of the roller, usually made of metal or another sturdy material, is prepared. This involves machining the core to the desired dimensions and surface finish. The core may also be coated with a bonding agent to improve adhesion with the rubber.

- Rubber Mixing: Rubber compounds are prepared by mixing various ingredients such as natural or synthetic rubber polymers, fillers, plasticizers, curing agents, and additives. The specific formulation depends on the desired properties of the finished roller, such as hardness, flexibility, and resistance to wear.

- Molding or Extrusion: The rubber compound is then formed into the desired shape using either molding or extrusion processes. In molding, the rubber is injected into a mold cavity under pressure and heat, while in extrusion, the rubber is forced through a die to create a continuous profile of the desired diameter.

Second Phase of the Process

- Vulcanization: Vulcanization is the process of curing the rubber to improve its strength, elasticity, and durability. This is typically done by subjecting the molded or extruded rubber to heat and pressure in a vulcanization oven or autoclave for a specified period.

- Finishing: After vulcanization, the rubber drive roller may undergo additional finishing processes such as grinding, trimming, or polishing to achieve the desired dimensions and surface quality. Any excess material or imperfections are removed during this stage.

- Assembly: Once the rubber drive roller is complete, it may be assembled with other components such as bearings, shafts, or mounting hardware depending on its intended application.

- Quality Control: Throughout the manufacturing process, quality control checks are performed to ensure that the finished rollers meet the required specifications and performance standards. This may include dimensional measurements, hardness testing, visual inspection, and functional testing.